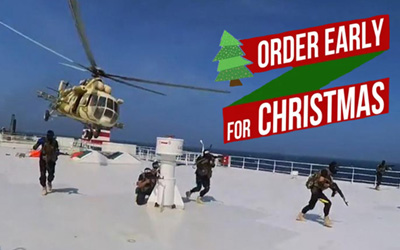

Businesses to Start Christmas Supply Chain Planning as Houthi Attacks Continue

In today’s volatile global market, supply chain disruptions have become all too common. The ongoing Houthi attacks are just one of many factors that can throw a wrench into the gears of global logistics. As we approach the festive season, businesses must start planning their Christmas supply chains early to navigate these challenges effectively.

Understanding the Houthi Attacks

The Houthi conflict, centered in Yemen, has been a source of significant instability in the region. The group has launched numerous attacks on key shipping routes and infrastructure, disrupting the flow of goods. These actions have far-reaching consequences, impacting global supply chains and causing delays and shortages in various industries.

The Importance of Early Christmas Supply Chain Planning

Why Early Planning Is Crucial

Why Early Planning Is Crucial

In a normal year, the holiday season already strains supply chains. With the added unpredictability of Houthi attacks, early planning becomes even more essential. Businesses that delay their planning risk running into severe bottlenecks, leading to missed sales opportunities and disappointed customers.

The Risks of Delayed Planning

Waiting too long to start planning can result in stockouts, increased costs, and the inability to meet customer demand. In the current climate, these risks are amplified, making proactive planning a non-negotiable for businesses aiming to capitalize on the holiday season.

Assessing the Impact of Houthi Attacks on Supply Chains

Direct and Indirect Effects

The direct effects of Houthi attacks include damage to shipping vessels and port facilities, leading to delays and rerouting. Indirectly, these attacks create a ripple effect, causing congestion and increased costs as shipping companies adjust their routes and schedules to avoid conflict zones.

Specific Industries Affected

Industries heavily reliant on international shipping, such as electronics, apparel, and consumer goods, are particularly vulnerable. The disruption can lead to significant delays and increased costs, impacting their ability to meet holiday demand.

Strategies for Mitigating Supply Chain Disruptions

Diversifying Suppliers

Diversifying Suppliers

One of the most effective ways to mitigate disruptions is to diversify your supplier base. Relying on a single supplier or region increases vulnerability. By spreading risk across multiple suppliers, businesses can better navigate unexpected disruptions.

Increasing Inventory Levels

While carrying higher inventory levels comes with its own set of challenges, it can be a valuable strategy in uncertain times. This approach ensures that businesses have enough stock to meet demand, even if supply lines are temporarily disrupted.

Utilizing Technology for Better Visibility

Modern supply chain management tools offer real-time tracking and analytics, providing businesses with greater visibility into their operations. These tools can help identify potential issues before they become critical, allowing for quicker response times.

Diversifying Suppliers

Benefits of Multiple Suppliers

Having multiple suppliers reduces the risk of total disruption if one supplier faces issues. It also fosters competition among suppliers, potentially leading to better prices and terms.

Finding and Vetting New Suppliers

Expanding your supplier base involves thorough research and vetting. Look for suppliers with a proven track record of reliability and quality. Establish clear communication and expectations from the start to build strong partnerships.

Increasing Inventory Levels Advantages and Disadvantages

The main advantage of higher inventory levels is the ability to meet demand during disruptions. However, this approach requires more storage space and increased capital tied up in stock. Businesses must weigh these factors and find a balance that works for them.

Managing Increased Inventory Effectively

Effective inventory management involves accurate forecasting, efficient storage solutions, and regular inventory audits. Using technology to track inventory levels can help optimize stock levels and reduce the risk of overstocking.

Utilizing Technology for Better Visibility

Utilizing Technology for Better Visibility

Tools and Software for Supply Chain Management

Invest in supply chain management software that offers real-time tracking, predictive analytics, and automation. These tools can streamline operations, improve efficiency, and provide valuable insights into potential risks.

Real-time Tracking and Analytics

Real-time tracking allows businesses to monitor shipments and inventory levels continuously. Predictive analytics can forecast potential disruptions, giving businesses the information they need to make proactive adjustments.

Strengthening Relationships with Existing Suppliers

Importance of Communication and Collaboration

Strong communication with suppliers can lead to better coordination and problem-solving. Regular updates and collaborative planning can help mitigate the impact of disruptions and ensure smoother operations.

Building Stronger Partnerships

Investing in long-term relationships with key suppliers can lead to better terms, reliability, and mutual support during crises. Consider strategic partnerships and joint ventures as ways to strengthen these ties.

Enhancing Transportation and Logistics Strategies

Optimising Routes and Methods

Review and optimize transportation routes to reduce dependency on vulnerable areas. Consider alternative shipping methods, such as air freight or rail, to diversify logistics options.

Collaborating with Logistics Providers

Collaborating with Logistics Providers

Work closely with logistics providers to develop flexible and resilient shipping plans. This collaboration can include contingency plans for rerouting shipments and adjusting schedules as needed.

Focusing on Risk Management Identifying Potential Risks

Conduct a thorough risk assessment to identify potential vulnerabilities in your supply chain. This assessment should cover all aspects, from supplier reliability to geopolitical risks.

Developing Contingency Plans

Develop detailed contingency plans for various scenarios, including supplier disruptions, transportation delays, and unexpected demand spikes. Regularly review and update these plans to ensure they remain effective.

Leveraging Local Suppliers

Reducing Dependence on International Shipping

Sourcing locally can reduce the risks associated with international shipping disruptions. Local suppliers can offer faster lead times and more predictable delivery schedules.

Benefits of Local Sourcing

Local sourcing supports the local economy and can lead to stronger community ties. It also reduces transportation costs and environmental impact, aligning with sustainability goals.

Conclusion

Proactive planning and strategic adjustments are essential for businesses to navigate the current landscape of supply chain disruptions. By diversifying suppliers, leveraging technology, and building strong relationships, businesses can ensure a smoother holiday season despite ongoing challenges.

FAQ

Why is early Christmas supply chain planning important?

Early planning helps businesses anticipate and mitigate potential disruptions, ensuring they can meet holiday demand and avoid stockouts and increased costs.

How do Houthi attacks impact global supply chains?

Houthi attacks disrupt key shipping routes and infrastructure, causing delays and increased costs for businesses reliant on international shipping.

What are some effective strategies for mitigating supply chain disruptions?

Diversifying suppliers, increasing inventory levels, utilizing technology for better visibility, and strengthening relationships with existing suppliers are effective strategies.

How can technology help in supply chain management?

Technology provides real-time tracking, predictive analytics, and automation

SARR Logistics UK

With a legacy built on trust, backed by extensive experience, a global network, and a customer-centric approach, SARR Logistics UK emerges as the ultimate partner for all your supply chain mapping needs. We are in touch with the latest cloud base systems and tracking systems, if you would like to know more reach out to us today and experience a seamless, efficient, and dependable shipping solution tailored to elevate your business. For further inquiries and to explore how SARR Logistics UK can help you contact our team today.![]()

Why Early Planning Is Crucial

Why Early Planning Is Crucial Diversifying Suppliers

Diversifying Suppliers Utilizing Technology for Better Visibility

Utilizing Technology for Better Visibility Collaborating with Logistics Providers

Collaborating with Logistics Providers