How JIT Can Transform your supply chain management

In today’s fast-paced business environment, companies are continuously seeking ways to enhance efficiency, reduce costs, and stay competitive. One strategy that has gained significant traction is Just In Time delivery. This approach revolutionises supply chain management by minimising inventory levels and ensuring that materials and products are delivered exactly when needed. In this post, we will delve into the concept of Just in time delivery, its benefits, implementation strategies, and its impact on various industries.

Understanding (JIT) Just In Time Delivery

Definition of JIT Delivery

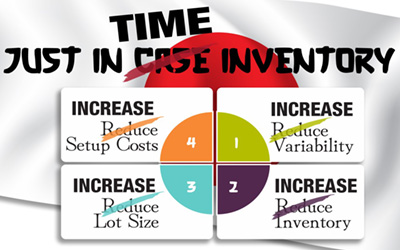

Just In Time delivery is a supply chain management strategy that focuses on reducing waste and improving efficiency by receiving goods only as they are needed in the production process. This method contrasts with traditional inventory systems that rely on maintaining large stocks of materials. JIT delivery aims to minimise inventory costs and reduce the time goods spend in storage.

Historical Background of JIT

The concept of Just In Time delivery originated in Japan, particularly within the automotive industry. Toyota Motor Corporation is widely recognised as a pioneer in implementing JIT principles in the 1970s. The goal was to enhance production efficiency and eliminate waste, thereby leading to the development of the renowned Toyota Production System (TPS). This approach has since been adopted by numerous industries worldwide.

Core Principles of JIT Delivery

JIT delivery is founded on several core principles, including:

Demand-driven production:

Manufacturing processes are driven by customer demand rather than forecasts, ensuring that products are made only when there is a need.

Continuous improvement:

Companies continuously seek ways to streamline processes and eliminate inefficiencies, often through methods such as Kaizen, a Japanese term meaning change for the better or continuous improvement.

Quality control:

Emphasis on high-quality production processes to reduce defects and rework, ensuring that products meet customer expectations.

Advantages of JIT Delivery

Cost Reduction

One of the primary benefits of JIT delivery is cost reduction. By minimising inventory levels, companies can significantly cut down on storage costs, including warehousing, insurance, and handling expenses. Additionally, JIT reduces the risk of obsolescence and excess inventory, which can lead to financial losses.

Enhanced Efficiency

JIT delivery promotes streamlined operations by aligning production schedules with actual demand. This synchronisation eliminates bottlenecks, reduces lead times, and ensures that resources are used efficiently. As a result, companies can respond more swiftly to market changes and customer requirements.

Improved Product Quality

With a focus on continuous improvement and quality control, JIT delivery enhances product quality. Since production is closely monitored and defects are quickly identified, companies can implement corrective measures promptly. This leads to higher customer satisfaction and a stronger reputation for reliability.

Implementing JIT Delivery

Assessing Readiness for JIT

Before implementing JIT delivery, companies must assess their readiness for this approach. This involves evaluating current processes, identifying potential challenges, and determining if the organisation has the necessary resources and capabilities. Key factors to consider include supplier reliability, production flexibility, and workforce readiness.

Building Strong Supplier Relationships

Successful JIT implementation relies heavily on strong relationships with suppliers. Companies must work closely with their suppliers to ensure timely and consistent delivery of materials. This often involves establishing long-term contracts, improving communication channels, and collaborating on quality improvement initiatives.

Adopting Lean Manufacturing Practices

Lean manufacturing practices are integral to JIT delivery. These practices focus on eliminating waste, optimising processes and enhancing value. Techniques such as value stream mapping and Total Productive Maintenance (TPM) are commonly used to support JIT implementation.

Challenges of JIT Delivery

Supplier Dependence

One of the significant challenges of JIT delivery is supplier dependence. Since JIT requires frequent and timely deliveries, any disruption in the supply chain can have a significant impact on production. Companies must carefully select reliable suppliers and develop contingency plans to mitigate risks.

Demand Variability

JIT delivery is highly sensitive to demand variability. Fluctuations in customer demand can disrupt the smooth flow of materials and lead to production delays. To address this challenge, companies need robust demand forecasting and flexible production systems that can adapt to changes quickly.

Initial Implementation Costs

Implementing JIT delivery can involve substantial initial costs. Investments may be required for process reengineering, employee training, and technology upgrades. However, these costs are often offset by the long-term benefits of reduced inventory expenses and improved efficiency.

Future Trends in JIT Delivery

Sustainable Practices

Sustainable Practices

Sustainability is becoming increasingly important in supply chain management. Future trends in JIT delivery include integrating sustainable practices, such as reducing carbon footprints, minimizing waste, and using eco-friendly packaging. Companies are also exploring renewable energy sources and green logistics to support JIT initiatives.

Advanced Technologies

Advancements in technology will continue to shape the future of JIT delivery. Innovations such as artificial intelligence (AI), machine learning, and blockchain are expected to enhance supply chain visibility, predict demand more accurately, and improve overall efficiency. These technologies will enable companies to implement JIT delivery more effectively.

Resilience and Risk Management

The COVID-19 pandemic highlighted the need for supply chain resilience and risk management. Future JIT delivery strategies will focus on building resilient supply chains that can withstand disruptions. This includes diversifying supplier bases, implementing contingency plans, and leveraging technology to monitor and mitigate risks.

Case Studies of Successful JIT Implementation

Toyota Motor Corporation

Toyota Motor Corporation

Toyota’s success of Just In Time delivery is a well-documented case study. The company’s commitment to continuous improvement and waste reduction has made it a global leader in the automotive industry. Toyota’s JIT practices have enabled it to maintain high production efficiency, minimise inventory costs, and deliver high-quality vehicles.

Dell Technologies

Dell Technologies is another example of successful JIT implementation. By adopting a direct-to-consumer business model and implementing JIT principles. Dell has been able to reduce inventory levels, shorten lead times, and customise products to meet customer preferences. This approach has given Dell a competitive edge in the electronics market.

McDonald’s

In the fast-food industry, McDonald’s has effectively utilised JIT delivery to manage its supply chain. By coordinating with suppliers and optimising inventory levels. McDonald’s ensures that its restaurants receive fresh ingredients as needed. This approach supports the company’s commitment to quality and customer satisfaction.

Summery

Just In Time delivery is a transformative approach to supply chain management that offers numerous benefits, including cost reduction, enhanced efficiency, and improved product quality. While implementing JIT delivery poses challenges such as supplier dependence and demand variability, its advantages make it a valuable strategy for various industries.

By leveraging technology and adopting best practices, companies can successfully implement JIT delivery and achieve a competitive edge in today’s dynamic business environment. As industries continue to evolve, the future of JIT delivery will be shaped by sustainability, advanced technologies, and resilience, ensuring its relevance and effectiveness in the years to come.

SARR Logistics UK

With a legacy built on trust, backed by extensive experience, a global network, and a customer-centric approach, SARR Logistics UK emerges as the ultimate 4PL logistics partner for all your freight forwarding and supply chain needs. For further inquiries and to explore how SARR Logistics UK can help you contact our team today.

Sustainable Practices

Sustainable Practices Toyota Motor Corporation

Toyota Motor Corporation